The electroplating market has been growing rapidly owing to the wide applications of electroplating in various end-use industries such as automotive, electrical & electronics, aerospace & defence and others. Electroplating offers corrosion resistance, wear resistance and improves the aesthetic appearance of components. It involves coating a thin layer of metal such as chrome, nickel or copper on substrate materials such as plastic & metals through an electrochemical process. The process helps in improving hardness, lubricity and electrical conductivity of surfaces.

The Global electroplating market is estimated to be valued at US$ 22.27 Bn in 2024 and is expected to exhibit a CAGR of 6.0% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the electroplating market are Philips Healthcare, GE Healthcare, Siemens Health, Toshiba Medical Systems, Shimadzu Medical, Ziehm Imaging, Hitachi Medical Systems, Orthoscan Inc. and Hologic Corporation. The wide range of applications has created substantial growth opportunities for market players in the coming years.

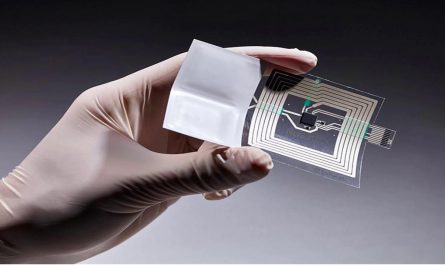

Electroplating Market Size finds applications in manufacturing micromachines, microelectronics, MEMS and other miniaturized devices where corrosion resistance and wear resistance is highly essential. Rapid advancements in nanotechnology have further expanded the scope of electroplating. Techniques such as nano-electroplating are enabling uniform and ultra-thin coatings required for miniaturized electronics and medical devices.

Market Drivers

Growing demand from the automotive industry is a key factor driving the electroplating market. Electroplating helps in providing protective, decorative and functional coating on various automotive components exposed to corrosion. Electroplated parts exhibit longer lifespan and require less maintenance. Rising vehicle production across the world especially in developing economies is propelling the consumption of electroplating for automotive applications. Electroplated components are increasingly replacing plastic and die-cast parts due to their superior properties. This is poised to favor the market expansion over the coming years.

Current challenges in Electroplating industry:

The electroplating industry faces several challenges which hampers its growth. Strict environmental regulations around the use of chemicals is one of the major challenge. Heavy metals like chromium, nickel and lead used in electroplating are toxic in nature and their discharge into environment is regulated. Secondly, increasing raw material costs puts pressure on profit margins of companies. Metals like zinc, copper, chromium etc requires for electroplating process sees fluctuating prices in global markets. Further, availability of skilled workforce is also a challenge as electroplating needs technicians with expertise.

SWOT Analysis

Strength: Electroplating provides corrosion resistance and improves aesthetics of materials. It allows uniform deposition of metal coating on complex shapes and contours.

Weakness: Initial set up requires high capital investment in electroplating equipment and technology. stringent environmental norms increases compliance cost.

Opportunity: Growing automotive industry worldwide drives demand for electroplated components. Aerospace sector also offers new areas of growth. Adoption of new plating techniques to plate non-conductive surfaces opens up opportunities.

Threats: Substitution threat from alternative surface coating technologies like physical vapor deposition (PVD). Stricter environmental laws around the world poses regulatory challenges.

In terms of value, North America dominated the electroplating market in 2024. Presence of major automotive production clusters in the US and Mexico drives electroplating consumption. Another fastest growing regional market is Asia Pacific. Countries like China, India and Japan are witnessing rise in automobile manufacturing which stimulates demand for electroplated auto parts.

Automotive and electrical & electronics industries accounts for over 60% share of electroplating consumption globally. Components used in these sectors widely adopt metal plating for protection against corrosion and wear & tear. Future growth prospects also remains high for electroplating in industrial machinery, aerospace and defense applications. New application areas and emerging technologies adoption will push the boundaries of electroplating industry in coming years.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it