Need for an On-board Fuel Monitoring System

Offshore support vessels typically consume large quantities of fuel for their propulsion and power generation needs. Without a centralized monitoring system, it is difficult to keep track of daily and monthly fuel consumption patterns. Some key issues faced due to the lack of an onboard fuel monitoring system include unexpected increase in fuel costs, inability to detect fuel leakage or theft, challenges in budgeting and planning fuel requirements and procurement. A fuel monitoring system addresses these issues by providing real-time data on fuel tank levels, daily and voyage fuel consumption. It helps optimize bunkering and reduce the risk of running out of fuel during offshore operations.

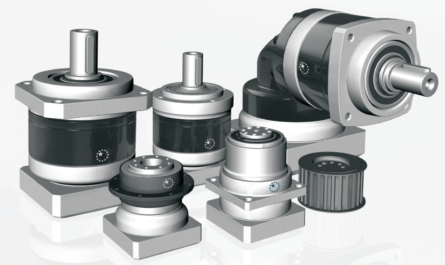

System Components and Installation

A typical onboard fuel monitoring system comprises of fuel level sensors installed on each fuel tank, a central control unit or monitoring panel and data connectivity via cables or wireless technology. Magnetic or float based level sensors continuously measure the fuel volume in each tank and transmit the data to the central control unit. The control unit collates and displays the fuel level and consumption data on an easy-to-use interface. System installation involves routing cables from sensors to the control panel and setting up the required interfaces and networking. Proper calibration is done to ensure accurate level and volume measurement. Cloud-based systems also enable remote access and monitoring of vessel fuel data from shore offices.

Real-time Monitoring and Data Analytics

With sensors continuously feeding data, the onboard Offshore Support Vessel On-board Fuel Monitoring System provides real-time visibility of fuel levels across all tanks from a single dashboard. Dynamic tank-wise or ship-wide fuel volume graphs help track bunkering, daily consumption and remaining fuel onboard. Alarms can be programmed for minimum fuel level thresholds. Historical consumption data over days, weeks and months can be retrieved to analyze bunkering and operating patterns. Machine learning algorithms on this historical data help forecast future fuel requirements and detect abnormal fuel usage. Data logs maintained by the system aid audits, investigations and ensure regulatory compliance.

Fuel Consumption Optimization

Leveraging the insights from real-time and historical fuel data analysis, vessel crews and managers can optimize daily operations and bunkering plans to reduce fuel consumption. Route planning based on prevailing weather and sea conditions helps burn lesser fuel. Tracking engine-wise or equipment-wise fuel usage highlights areas for improved efficiency. Tweaking engine parameters, slow steaming during idling legs and optimized ballast handling further boosts fuel efficiency. Bunkering is planned just-in-time to avoid carrying excess fuel while ensuring safe fuel reserves. Overall, these optimization measures lead to annual savings running into hundreds of thousands of dollars in fuel costs for vessel owners.

System Health Monitoring and Maintenance

Being an critical system for safe and efficient vessel operations, the onboard fuel monitoring system also requires scheduled maintenance and performance monitoring. Regular sensor calibration checks and system software/firmware upgrades are carried out during docking periods. Network cables and interfaces are inspected for signs of wear and repairs are carried out.24×7 system uptime is ensured through redundant power backup and automatic switch to standby mode in case of primary component failure. Cloud server health, remote access functionality and data security are also actively monitored. Periodic system audits evaluate fuel usage patterns to detect sensor faults at the earliest. With proactive maintenance, the fuel monitoring equipment serves vessel operations trouble-free for over 10 years of design life.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it